The modern oil & gas industry runs on performance, predictability and safety. But behind every stable wellbore, free-flowing pipeline and on-spec fuel lies a carefully engineered set of speciality chemicals and additives – from drilling mud modifiers to demulsifiers, corrosion inhibitors, pour point depressants and anti-foaming agents.

Under the CRISTOL brand, Krishna Antioxidants Pvt. Ltd. (KAPL) has been formulating and manufacturing such high-performance speciality chemicals since 1991 – giving the company 32+ years of manufacturing experience across sophisticated chemistries. Today, Cristol serves upstream, downstream and petrochemicals along with other demanding industries like agrochemicals, textiles and personal care.

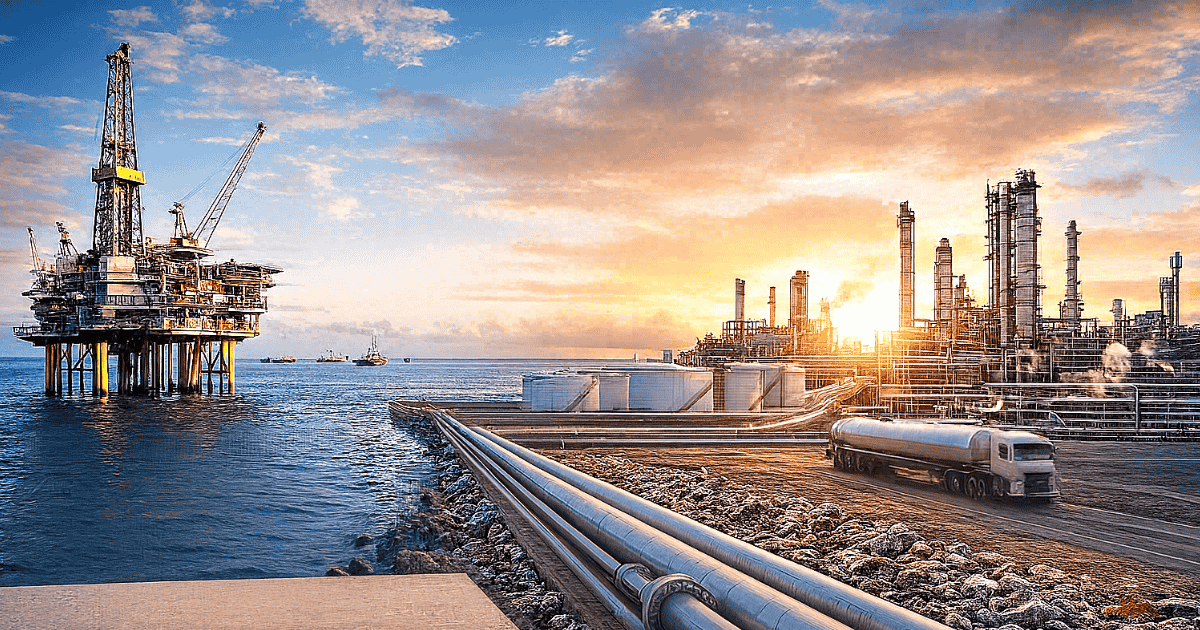

This blog walks through how CRISTOL’s specialty chemicals create value at every step of the oil & gas chain – from the wellhead to the refinery – while maintaining stringent international QHSE and regulatory standards.

At a high level, the oil & gas value chain can be viewed in four stages:

Speciality chemicals and additives are embedded in each of these steps to control rheology, prevent deposits, manage emulsions, reduce corrosion, suppress foam and stabilise fuels. Global operators increasingly rely on such solutions to boost recovery, meet environmental regulations and extend asset life.

CRISTOL’s portfolio is structured around this value chain, with dedicated ranges for drilling fluid chemicals, production chemicals and refinery additives.

Drilling is one of the most technically demanding and cost-intensive phases of any field development. As operators drill deeper, hotter and through more complex formations, drilling fluids and their additives must perform flawlessly.

CRISTOL’s Drilling Fluid Chemicals are custom-formulated systems and additives designed to:

Typical CRISTOL drilling-related speciality chemicals include:

Because CRISTOL works as a speciality chemical formulator, these products are not generic commodities. They are tailored to specific drilling systems (water-based, oil-based, synthetic-based) and basin conditions, helping operators reduce NPT and total cost per metre drilled.

Once wells are onstream, the challenge shifts to keeping production steady, safe and economical over the life of the field. Produced fluids are complex emulsions of oil, gas, water and solids, often under sour and scaling conditions.

CRISTOL’s Production Chemicals are engineered to deal with these multiphase realities, focusing on:

Key speciality chemical categories in the CRISTOL production portfolio include:

Together, these chemistries maximise recoverable reserves, reduce unplanned shutdowns and help operators meet increasingly strict water disposal and emission norms.

Between the wellhead and refinery, crude and condensate travel through gathering systems, trunk pipelines, terminals and storage tanks. Poorly controlled wax, asphaltenes, scale and sludge can choke capacity, increase pumping power and drive costly pigging or chemical clean-ups.

CRISTOL’s production and flow assurance chemicals extend into these midstream operations by:

These are typical applications where fit-for-purpose speciality additives can unlock significant OPEX savings and defer major capital interventions.

At the downstream end, refiners must handle a wider slate of crudes while meeting tighter fuel standards and emission regulations. This places pressure on crude compatibility, equipment reliability and fuel performance.

CRISTOL’s Refinery Chemicals portfolio focuses on:

By combining process understanding with application-specific additives, Cristol works with refiners to address:

This completes the “wellhead to refinery” spectrum – ensuring that the chemistry driving production also supports reliable and compliant refining operations.

Cristol’s ability to support the entire oil & gas value chain rests on a strong manufacturing and regulatory foundation:

This combination gives global operators confidence that CRISTOL products are manufactured under rigorous QHSE and regulatory frameworks – a crucial differentiator as environmental and safety expectations continue to rise.

CRISTOL’s innovation engine is not limited to oil & gas. The company’s speciality chemicals are used across:

This multi-industry footprint is important for oil & gas customers because it:

For many oil & gas companies, the real competitive edge lies in proprietary formulations or niche chemistries tuned to a specific basin, reservoir or process. Building in-house manufacturing capacity for every such product is rarely economical.

Cristol addresses this gap through custom / contract manufacturing (toll manufacturing) and custom formulation services:

For oil & gas operators and service companies, this means:

Bringing it all together, CRISTOL’s value proposition to the oil & gas sector can be summarised as:

For operators, refiners and service companies looking to derisk operations, meet regulatory expectations and unlock more value from their assets, partnering with CRISTOL provides a chemistry-plus-manufacturing solution – from the wellhead all the way to the refinery.

FAQs

1. What types of specialty chemicals does CRISTOL supply for the oil & gas sector?

CRISTOL supplies drilling fluid chemicals, production chemicals (including demulsifiers, flow improvers, corrosion and scale inhibitors, H₂S scavengers, anti-foaming agents and sludge breakers) and refinery additives focused on fuel treatment and performance enhancement across the oil & gas value chain.

2. At which stages of the oil & gas value chain can CRISTOL products be used?

CRISTOL products are used from the upstream phase (drilling and completion) through production and flow assurance, into midstream transport and storage, and finally in refining and petrochemicals for fuel treatment and performance additives.

3. Does CRISTOL offer custom-made oilfield chemical formulations?

Yes. Through its custom / contract manufacturing services, CRISTOL develops and produces customer-specific formulations under confidentiality, backed by in-house R&D, pilot plants, flexible reactors and on-site testing capabilities.

4. What certifications and regulatory standards does CRISTOL comply with?

Cristol (KAPL) operates under ISO 9001, ISO 14001 and ISO 45001 management systems, is GMP certified and REACH compliant, with a dedicated regulatory team supporting customers across regions.

5. How does CRISTOL support sustainability and HSE requirements in oil & gas operations?

Cristol’s integrated QHSE systems, environmental certifications and focus on high-performance chemistries (such as efficient demulsifiers, corrosion inhibitors and flow improvers) help operators reduce energy use, minimise unplanned downtime and meet environmental discharge and emission standards.

6. Does CRISTOL serve industries beyond oil & gas?

Yes. CRISTOL is active in agrochemicals, textiles, water treatment, castor oil derivatives, personal care and other speciality segments, leveraging cross-industry R&D and manufacturing expertise.

7. Can CRISTOL support export markets and international customers?

Cristol has a strong export footprint and aims to be recognised globally as a reliable producer of speciality chemicals for oil, gas and petrochemical sectors, supported by international certifications and a worldwide agent network.

8. How can an operator or service company start a toll manufacturing engagement with CRISTOL?

Prospective partners can reach out via the CRISTOL Custom Manufacturing or Contact Us pages, share basic product and application details, and then work with CRISTOL’s technical team to define formulation, scale-up plans, quality requirements and commercial terms.